Raising the mainsail of a Hobie can be more difficult than need be.

Several factors can cause the mainsail to be difficult to hoist: Dirty luff ropes and luff tracks. These can be cleaned with soapy water and a scrub brush. If you want to use a lubricant, keep away from oils and waxes that can attract dirt. Use a dry silicone spray. Most all Hobie sails now have a Teflon threaded bolt (luff) rope to ease the hoisting effort.

Battens and sail shape. The battens stiffen the airfoil shape of your sail. Over tensioning of the battens can cause a couple of problems. Luff protector caps can be forced against the mast and cause drag when hoisting. The battens also force the sail shape into a curve. The luff curve (seen when laying the sail out on the ground, as a large arch) is typical to Hobie Cat main sails. The sails "airfoil" shape is mostly created by the miss-matched mast bend and luff curve of the sail. The luff curve is more than the likely mast bend and when the mast is straight (while hoisting) the difference is dramatic. This luff curve going up the straight mast can cause significant drag and hoisting problems when done incorrectly.

Outhaul. Be sure the outhaul is fully released before hoisting.

Hoist Technique: Keep the batten tension to a minimum. Hoist the sail slowly, while feeding into the mast opening. When the sail gets about 3/4's of the way up, begin aggressively feeding at the bottom opening and reduce the amount of halyard effort. If the halyard is pulled tight when the sail is not being fed into and up the track, you will have problems. The sail luff will pull taunt and the curve shape will bind in the (straight) mast track. Lower the sail slightly and begin feeding again.

The best way to feed the sail is to stand in front of the mast and reach around either side to "sandwich" the sail between two hands (above the feeder opening) and push the sail up the track. Pull with the halyard, only the slack created, then feed again. If the sail binds, lower slightly and begin feeding again. This technique can be done by one person, but is certainly easier with two working together. It is VERY important that the person on the halyard only pulls the slack up the mast and does not get ahead of the feeder.

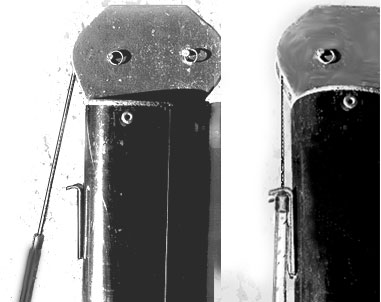

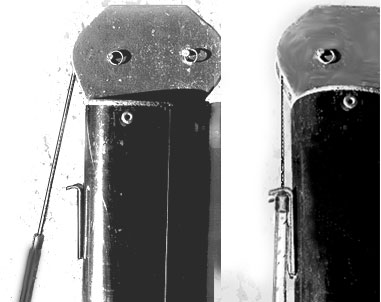

Locking the Hobie 14/16/Getaway halyard:Once the sail is fully hoisted (be sure that the sail is fully inserted into the feeder). Pull the halyard forward of the mast by 3-4 feet. Hold the halyard on the centerline of the mast. Pull hard and hold the tension while bringing the halyard into the mast. Release the halyard tension and see that the sail remains fully hoisted. This seats a small bead, in the halyard, under a two finger prong "hook" and the top of the mast. If the sail slips down when downhaul tension is added, repeat the final hoist technique again. Be sure the bead is clear to pass the hook before pulling tension on the halyard.

To release... fully release the downhaul and outhaul. Partially feed the sail up the luff track. Hoist with the halyard to the top till it stops,

hold... pull the halyard line forward 3-4 feet away from the mast, ease the halyard to lower the sail.

Locking the Hobie 17/18/20/21 Halyard:It is best to simulate the halyard locking with the mast down so you clearly understand the system.

Then, depending on how old the boat is, be sure the hook does not have the old "flopper" stainless piece hanging on the hook. This old device caused difficulty in raising and hooking but would make it easier to release and lower.

Also, be sure that the knot tied to the ring is very low profile. A long bowline knot will hit the mast head before the ring gets to the hook.

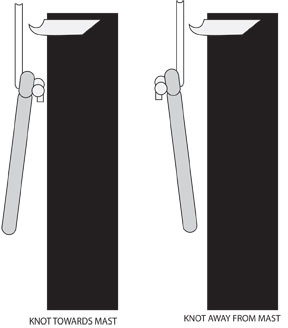

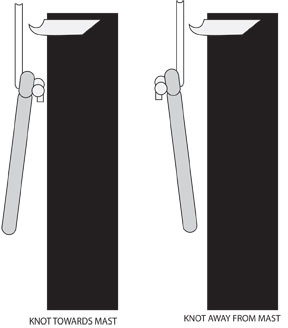

If the ring has a small loop at the top... The line should be passed through the loop and a small knot tied. The knot (when ring and shackle are affixed to the sail) should be facing the mast. This tilts the ring closer to the mast.

Then (before attaching halyard shackle to the sail) spin the halyard 3 or 4 times clockwise (looking down on the shackle). This "pre-loads" the halyard line and causes the ring to swing back towards the hook. Keep the boat into the wind and hoist. Should lock easily.

To release... fully release the downhaul and outhaul. Partially feed the sail up the luff track. Hoist with the halyard to the top till it stops, hold... rotate the aft of the mast base to starboard, hold the mast rotated, ease the halyard a few feet before releasing the mast. Lower the sail.