I have had difficulty turning right on my new Tandem Island when there is any tension on the rudder down control line. If there is light wind then no tension is required once you loosen the rudder bolt so the rudder sits in the slot. However, the rudder will pop out easily when the wind picks up without down tension. The more tension, the more difficult to turn right.

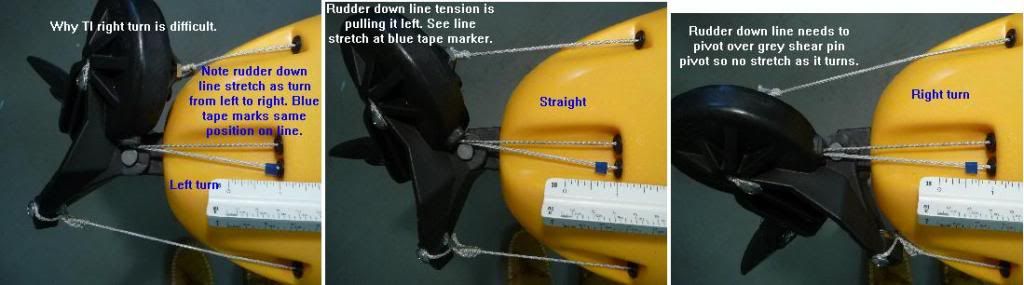

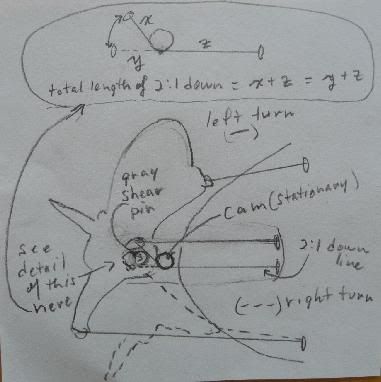

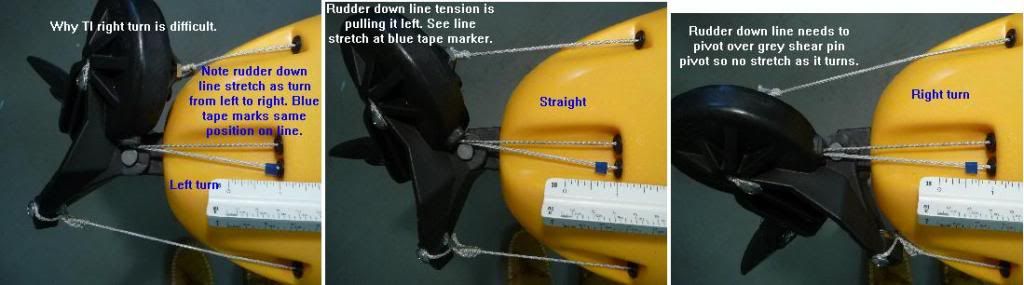

I looked at the rudder design to understand why, and it seems to be caused by the down control line not pivoting over the gray shear pin as it does with the AI. Since the control line enters the rudder off center from the rudder pivot, it acts as a left turn control line. The more tension, the more it pulls the rudder into a left turn. That may explain why it is so difficult to turn right when it is windy.

I made a three photo sequence showing the rudder down line stretch as you turn from left to right. A blue tape marker was placed on the down rudder control line to show how it stretches under the tension of a right turn. This seems to be an intrinsic property of the design so everyone should have the same problem, unless some have a different pivot mechanism on the TI rudder. See photo below to see stretch of down line as you turn from left to right.

Has anyone come up with a temporary solution? The best I can do now is tension the rudder down control line just enough to keep it from popping out. This means I have to continuously adjust this with every gust.

Bob