OK...here we go!

Tools

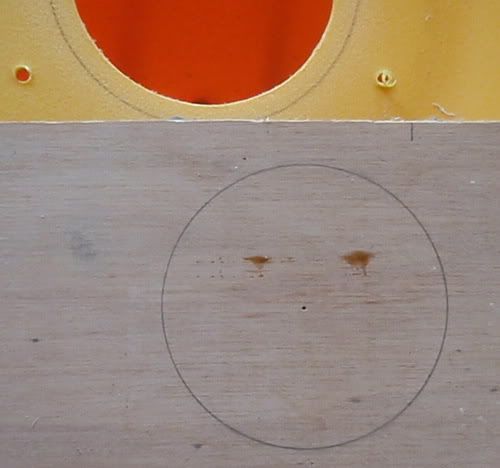

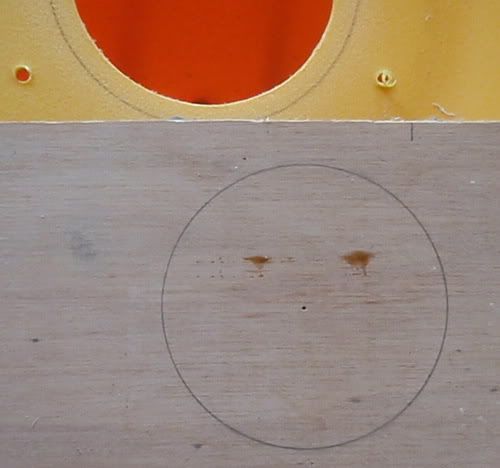

Measure diameter of hole in deck. using compass draw circle of same diameter onto a piece of ply making sure the point of the compass makes a visible pin prick in the centre of the circle, use a 2B pencil so your drawn line is reasonably thick.

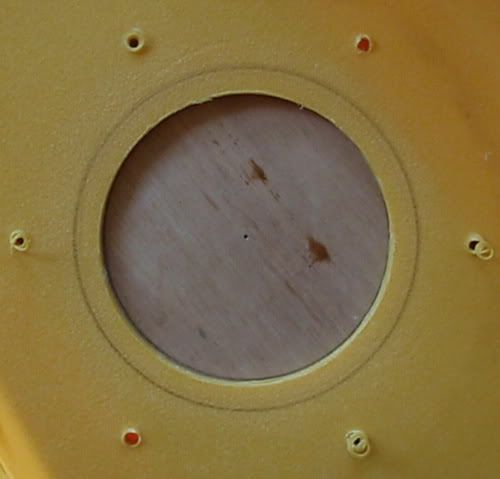

Using a prop to hold it firmly under the deck. Line the ply under the hole inside the deck so the circle youve drawn lies concentric to the hole in the deck. In other words get the holes to line up.

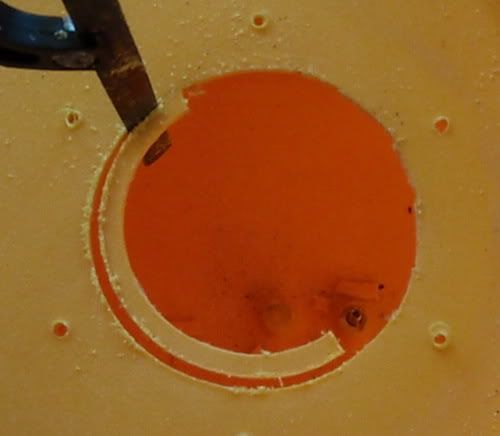

Now using the centre point outline the circle for the new hole onto the deck with your compass.

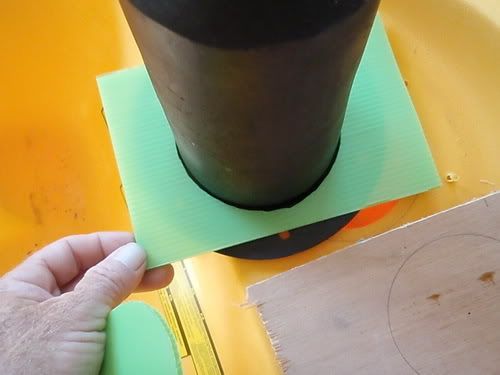

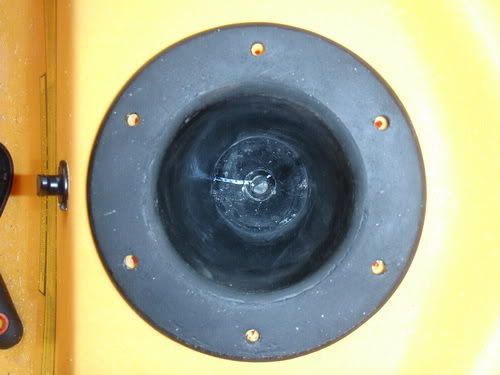

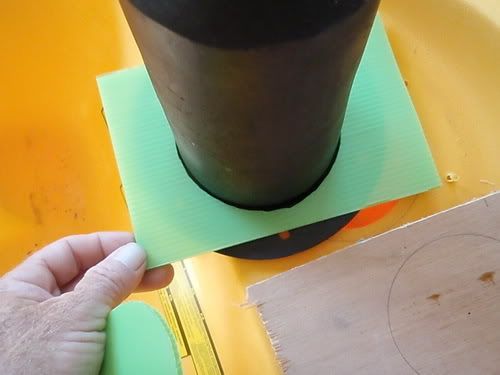

Before you start to cut the hole in the deck just cut your new hole into a sheet of plastic and slide your receiver through it to check the fit.

looks like theres some play which is good just in case my centre lines a bit off there will be enough room to fiddle the receiver so all the screw holes line up.

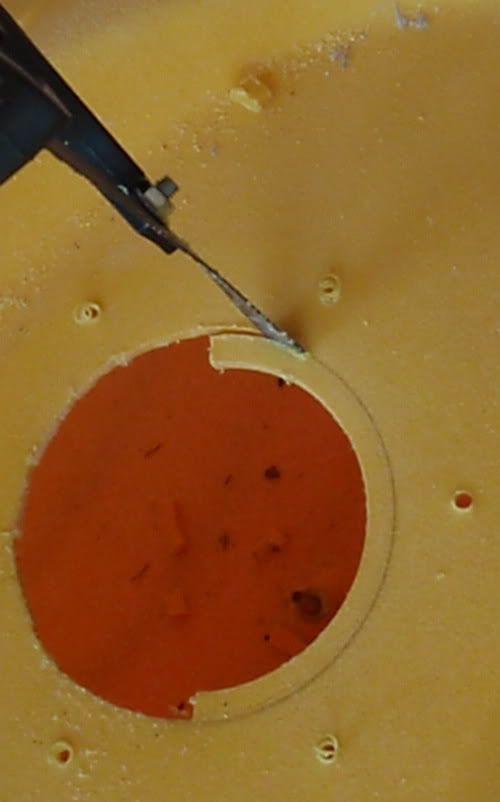

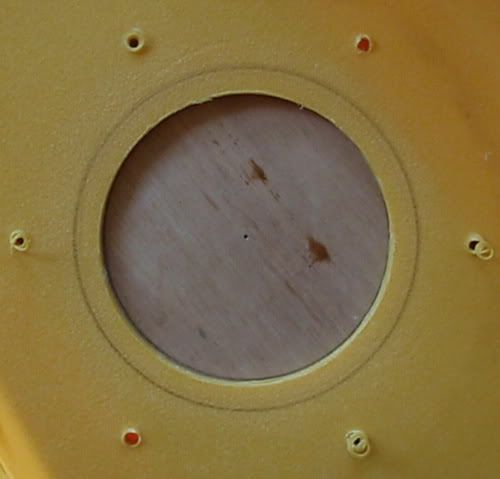

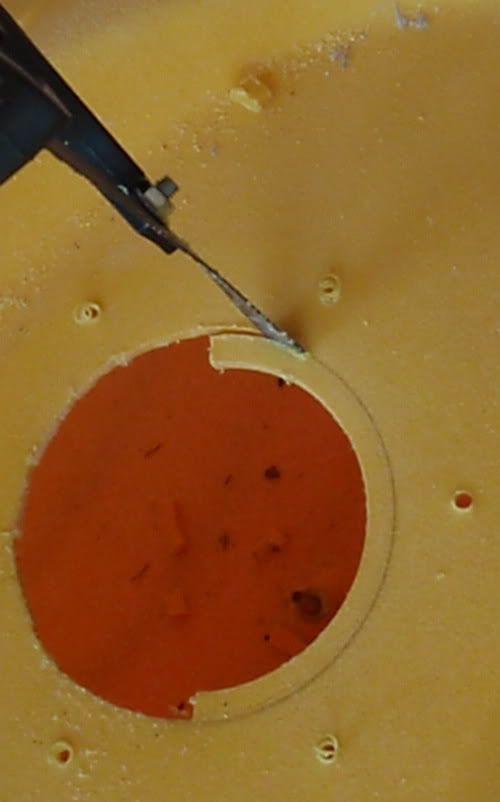

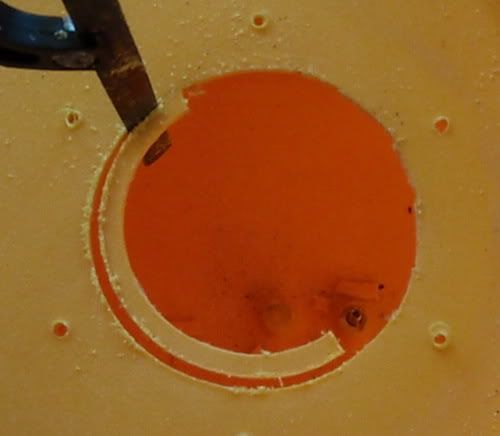

I am going to cut my hole using a hacksaw blade, there are some fantastic hole sawing devices you can mount onto your drill but they are quite expensive for a one off job and, as with any power tool, if you get it wrong...BOY does it ever GO WRONG. Also they all use a centre bit, that would require me to block up the inside of the hole with a big bit of timber. So I am going to go on with this by hand...noones going to see my hole anyway, it will be covered by the flange of the mast receiver.

Cut a slot out to take the width of your blade...this will keep you on the track of your line and keep you on radius, best way to cut the slot is cut outwards from the hole in the deck to your line in 10th" increments until you reach the correct width in my case 1/2", file back the little bits remaining with the edge of a file. Nows the important bit DONT do as I did (to start with) and use that part of the blade thats close to the frame of the saw you wont get enough twist to follow your line, the blade will track off. I soon wised up and just used the end of the blade which really twisted off well.

To prevent the blade binding use silicone spray. Short, rapid, light strokes only apply wrist pressure to maintain blade twist, dont saw too hard, you dont need to

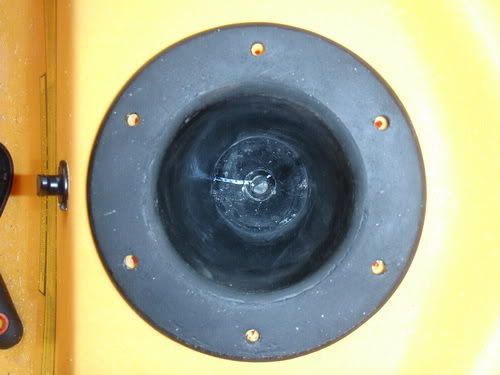

Now I have just put the receiver thru the hole in my deck and the screw holes are all lined up.

However it seems like its not seated tightly into the keel, theres an 1/8th inch gap. My compass fits between the receiver base and the keel

Aloha Dan says neither of his receivers are tight to the keel although they are firmly on the lugs. I think this is because the lugs flare out at the base and prevent the bottom of the receiver sitting firmly in the keel.

I understand that the V brace will take much of the load but I dont like the idea of everything pushing down on the lugs alone, I want the load spread across the keel so i am going to shim beneath the base of the receiver.

When I removed the receiver from my old hull the hole in the base was badly egged (See photo 'an ounce of prevention' posted Jan 10) as was the hole in the base plate of the V brace and thats stainless.

A lot of this was undoubtedly due to me not checking the tension of the brace nor checking the nut tension at the base of the receiver ... but I also feel (and stand to be corrected if I'm wrong) that had the receiver been hard into the keel the load would have been spread better. However, tightening down the nut still did not bring the receiver base in contact with the keel, it was hung up on the base of the lugs where they join into the keel....same problem as in the new hull.

Anyway now I am done nuts tight down and flush with the bolt on the lug, receiver seated hard on my shim

All thats left is to tweek the brace up so the mast fits OK and hopefully can getting sailing tommorow....its been a while!