Interesting discussion with some great ideas being put forward.

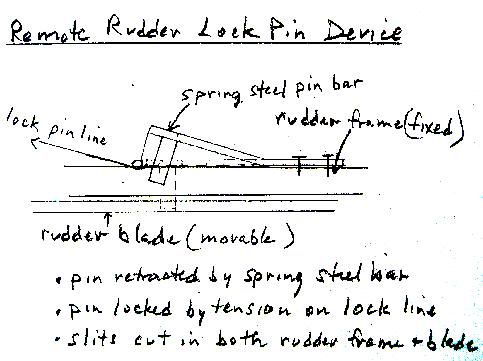

The remote locking pin seems like it would be a great idea.

Instead of remotely locking wouldn't it be better to remotely unlock?

That way there would be no extra tension on the rudder assembly from the lock down line.

I'm thinking of a pin through rudder blade and housing, with a spring that keeps it pushed through both. To lock the rudder pull the release line to withdraw the pin, drop the blade into place and release the line. Pin slides into place. Vice versa for raising.

I would not like to see the twist-n-stow rudder replaced with a pull up rudder. I had the original pull up rudder on my (Tandem) Oasis and it was difficult keeping it damage free. Anything that sticks out over the hull is prone to damage when transporting.

The larger TI rudder more so. An 18'6' hull becomes considerably longer when the rudder is raised.

BTW- It's not necessary to drill holes in the hull to run extra rudder lines. There is room in each tube to fit another spectra line. I had two lines coming out of each up/down line on my Oasis. They worked well. The newer rudder line tubes have an O-ring that could be removed to make room.