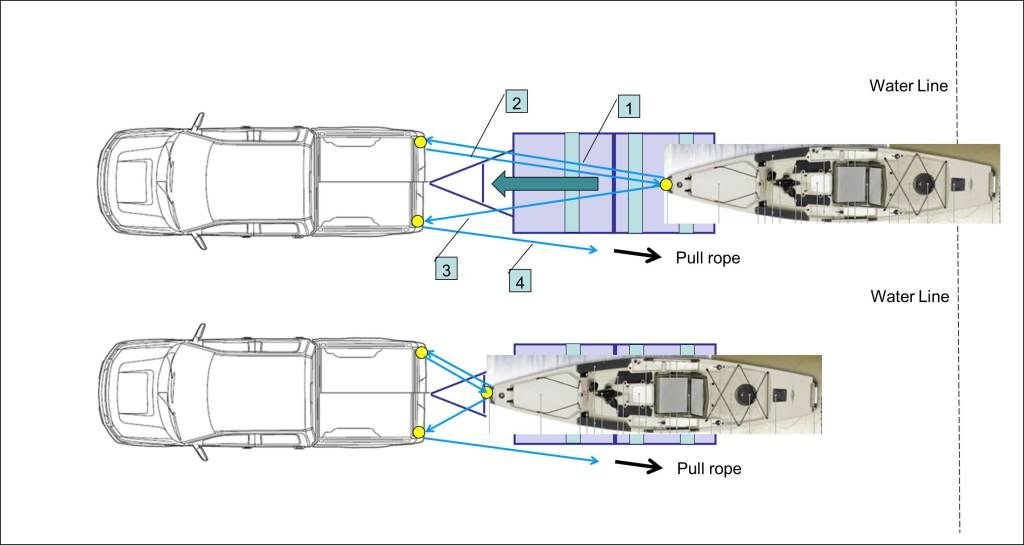

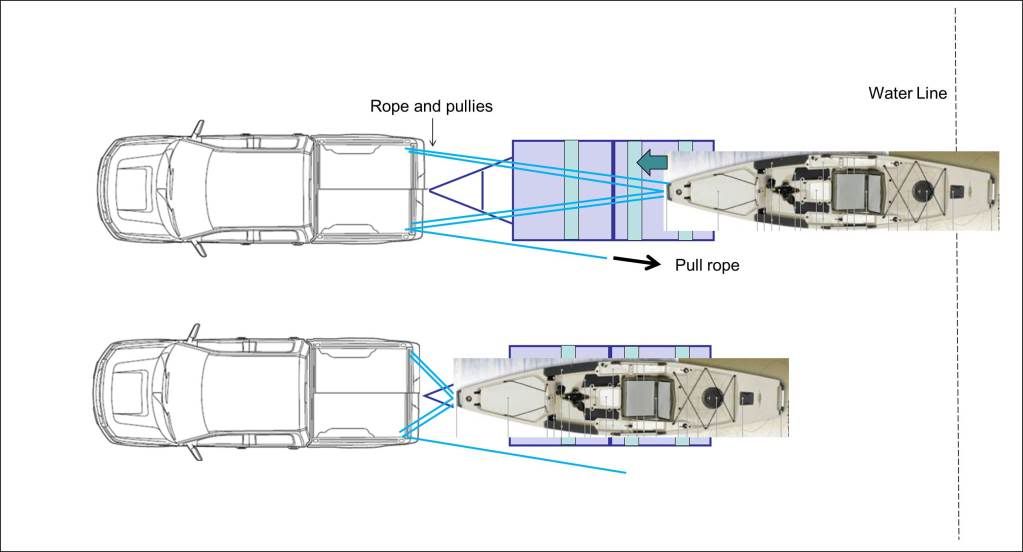

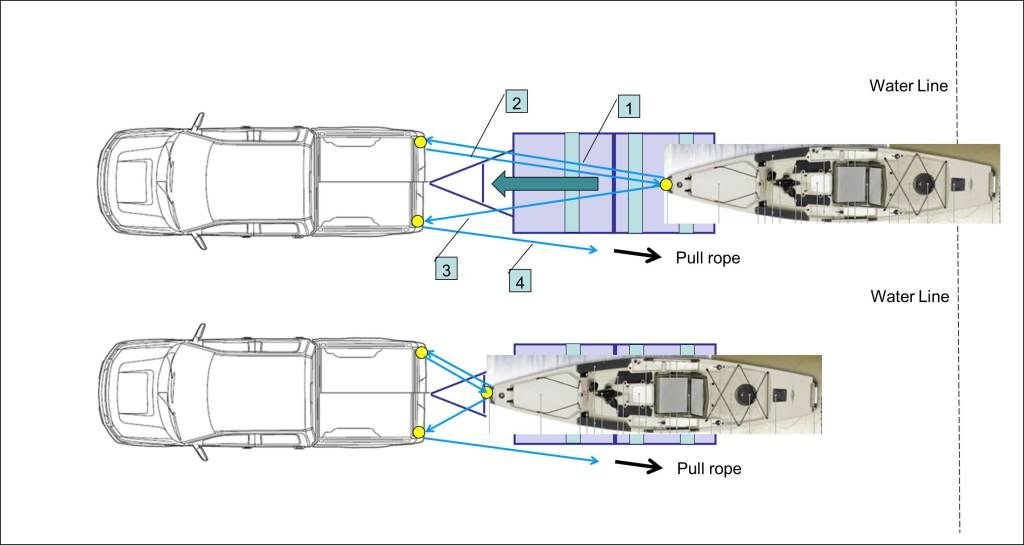

They are ~2" diameter pullies I got at the hardware store for a few bucks each - nothing special. The rope is 1/4" nylon rope/cord. Actually, my drawing is incorrect; I use one pulley at each location on the SUV/Truck and a one pulley on the front grab/carry handle of the PA. I made loops out of 12-18 inch lengths of cord so I can quickly loop-hitch them to the connection points, then attach the pullies via the small ring at the back end of each pulley (ID 3/8") via inexpensive, hardware-store carabiners. I pre-string the cord through the pullies with carabines attached so it's quick to set up in just a few steps. Takes two minuts to set it up. Next time I have it set up I'll take some pics or a video, but it's pretty straightforward.

For this purpose, the diameter of the pulley doesn't matter. The mechanical advantage of the pullies is directly proportional to the number of times you run the line back and forth between the PA and the SUV. My set up has four runs, so it provides 4X mechanical advantage and only 1/4 of the force/effort is required vs. the force required for a direct pull w/o the pullies. If you need to reduce the pull force further, you can add a pulley or two and increase the number of runs of line. Obviously, a longer lenth of rope is required.

I re-drew the drawing to correct it and labeled the runs and directions of line travel (below).

Run #1: from carabiner @ PA nose to right pulley @ SUV

Run #2: from right pulley @ SUV to pulley @ nose of PA

Run #3: from pulley @ PA nose to left pulley @ SUV

Run #4: from left pulley @ SUV to hand

Hope this helps. Let me know if you have any other questions.

Bob

PS: There are a number of alternative solutions. You could simply buy a small hand winch made for boat trailers. One designed for small boats is pretty cheap, but you need a place to mount it.