Howdy Russiet,

Yes, an epoxy. Quoting the company's website:

"When mixed together in equal portions, a chemical reaction occurs that turns the mixture into a compound as hard and tough as steel -- and with similar properties."

Their URL:

http://jbweld.net/products/jbweld.php

I'm pretty satisfied with the stuff, use it for many purposes. When I found some rivets loose, I removed the rivet, filled the hole, re-drilled and then re-riveted for a tight joint. Stuff works great.

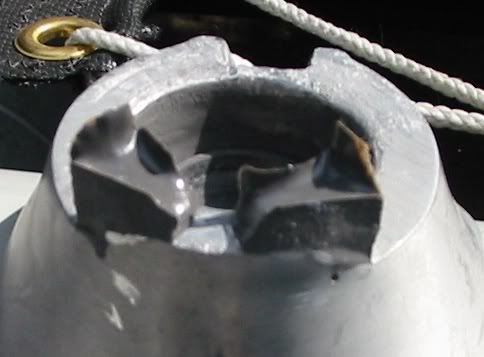

I think your base pivot fix should work OK. It's only in tension (pulling against the epoxy/strap while the mast is pinned and supported aft by the rear frame before you raise it. Otherwise it is in compression as you raise it and I'd expect the strap would mostly keep the base in place. I'd be more concerned with the rotational forces that this joint is subjected to as the mast is being raised and it tilts about it's axis. I use the newer style mast step link that resists tilting better than the old style. It's made out of beefier metal plate. At any rate, should this not work, I saw a mast base on available on Ebay if you're so inclined. Else, there's always the catalog purchase....your decision.

Else, I've put max rake on my '74 H16 and revised the way my mainsheet blocks are reeved. I can't wait to test it on the next sail. I've max raked before but found that I couldn't sheet-in block-to-block. This problem should be solved now. I've also installed a few more luff and leech tell-tales per the articles mentioned in another recent post.

I just hope the wind remains when I get out on the water.

Hope this helps